Typical applications for chemistry diaphragm pumps include evacuating chemically aggressive gases and vapors from such equipment as rotary evaporators, vacuum drying cabinets and centrifugal concentrators. Chemistry diaphragm pumps from VACUUBRAND feature uncompromising chemistry designs. Their construction with fluoropolymers makes them very resistant to chemical vapors from inlet to exhaust and very tolerant to condensates. Our two-, three- and four-stage pumps also have a gas ballast valve that provides continuous purge with minimal impact on ultimate vacuum when working with condensable vapors. Pumping chambers are hermetically separated from the drive system ensuring long lifetimes of mechanical parts. Most importantly, diaphragm pumps are oil-free, for vastly reduced service demands compared with oil-sealed pumps. They eliminate the cost of water and its contamination well-known from water-jet aspirators, and the waste-oil disposal of rotary vane pumps.

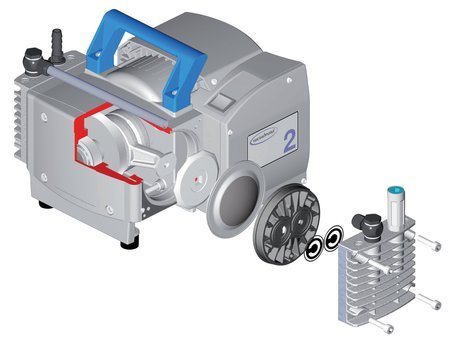

Rotary vane pumps are used whenever it is necessary to have a process vacuum of up to 10-3 mbar. VACUUBRAND rotary vane pumps are high-performance, yet compact, and can be equipped with an extensive line of VACUUBRAND accessories. They have an innovative lubrication system with a built-in oil pump and have a large oil volume. This extends oil change and service intervals and protects the pump at start-up. The effective gas ballast feature, with its high-flow gas ballast, provides high vapor pumping capability for water and solvents. VACUUBRAND rotary vane pumps´ volume flow rate is specified at atmospheric pressure, as is customary with PNEUROP®. For process effiency, however, the high volume flow rate of VACUUBRAND pumps under process conditions, as well as a consistently high volume flow rate over a wide pressure range, is the key to your satisfaction in real-world application. After switch-off the aggregate is vacuum-sealed to protect your application from undesired venting and oil back flow.

When intended for use in areas with potentially explosive atmospheres, European Community Directive 2014/34/EC (ATEX) requires equipment in conformity with ATEX standards. VACUUBRAND offers Category 2 chemistry diaphragm pumps and vacuum systems in conformity with ATEX (for use in zones where an explosive atmosphere is likely to occur). These chemistry diaphragm pumps are appropriate for such locations because they are highly resistant to chemicals, oil-free, have no sliding surfaces, and the expansion chamber is hermetically sealed against the drive zone. ATEX chemistry vacuum systems with solvent recovery provide safe, convenient vacuum while protecting the environment.

ATEX chemistry diaphragm pumps and vacuum systems are now available with variable speed motor for vacuum control as VARIO®-version.